BAM Develops Fingerprint Tech for 3D-Printed Parts

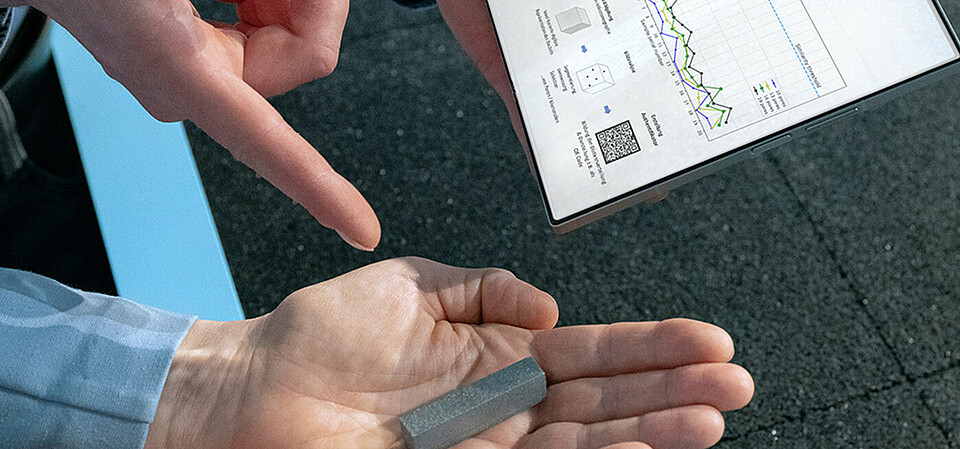

The digital object identifier links product data to real components in a unique and tamper-proof manner. © BAM

Berlin's Federal Institute for Materials Research and Testing (BAM) has developed a groundbreaking authentication method that makes 3D-printed parts as unique and traceable as human fingerprints. The innovative technology, for which BAM has already filed a European patent, addresses growing security concerns in additive manufacturing.

According to information from BAM's press release, the method exploits the naturally occurring microscopic structures within 3D-printed components. These tiny, randomly distributed features form during the printing process and cannot be replicated – much like biological fingerprints.

The authentication process uses high-resolution 3D micro-computed tomography to capture these internal structures. The imaging data is then converted into a geometric pattern and linked to a Digital Object Identifier (DOI), creating an unhackable connection between the physical component and its digital twin containing manufacturing data.

"Our method works without visible markings or interference with the printing process," explains project leader Anja Waske from BAM. "This makes it particularly secure against manipulation and opens new possibilities for product verification, logistics, and anti-counterfeiting measures."

The DOI4AM (Digital Object Identifier for Additive Manufacturing) project is developing a comprehensive workflow that enables component authentication through digital product passports. Various materials and geometries are being tested in real-world scenarios and integrated with existing software solutions.

BAM is collaborating with Paderborn-based Additive Marking, specialists in digital product identification for 3D printing. The company is expanding its Pass-X.eu platform with a new traceability module for additively manufactured components, providing quick access to CT service providers and integrating microstructure authentication.

The technology supports Germany's Quality Infrastructure Digital (QI-Digital) initiative, which promotes modern, data-based quality assurance focused on transparency, traceability, and trust throughout supply chains. The project receives funding from the Federal Ministry for Research, Technology and Space (BMFTR) under the DATIpilot funding program.