Mercedes Embraces AI and Robotics at Berlin Innovation Hub

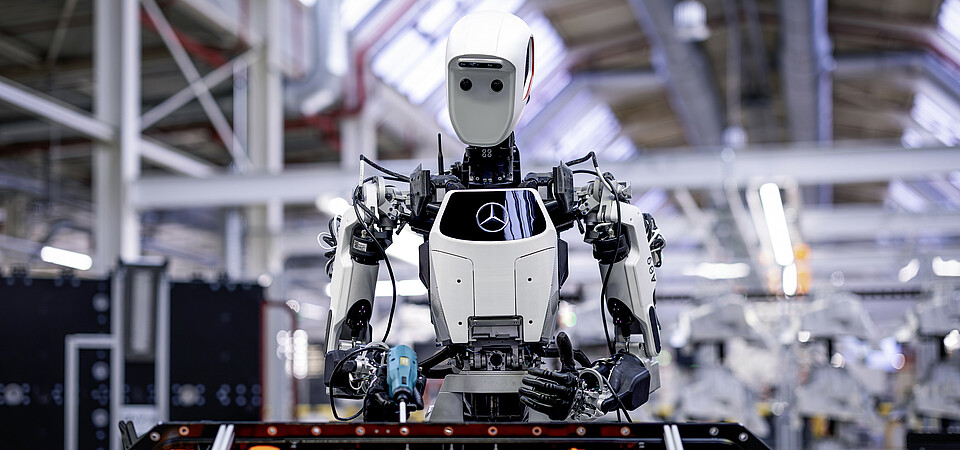

With Apollo, Mercedes-Benz brings one of world’s most advanced commercial humanoid robots into its manufacturing facilities - © Mercedes Benz

Mercedes-Benz is transforming automotive manufacturing by integrating artificial intelligence and humanoid robots at its Digital Factory Campus in Berlin-Marienfelde, according to a company press release.

The facility, established in 2022 as the global center for production digitalization, is reinforcing its status as an innovation hub with significant advancements in manufacturing technology. The campus serves as the development ground for the company's MO360 digital production ecosystem, which has now been enhanced with AI capabilities like the Digital Factory Chatbot Ecosystem and MO360LLM Suite.

In a bold move into robotics, Mercedes-Benz is investing a low double-digit million euro sum in Apptronik, bringing the company's advanced humanoid robot "Apollo" into its manufacturing facilities. Initially focused on intralogistics tasks, these robots can transport components to production lines and perform preliminary quality checks.

"Mercedes-Benz Berlin-Marienfelde remains at the cutting edge of automotive production and keeps Germany on the map as a global center for innovation," said Jörg Burzer, Board Member responsible for Production at Mercedes-Benz Group AG.

The Berlin campus is also pioneering AI applications that provide practical assistance to workers. The Digital Factory Chatbot allows employees to access production databases through simple conversational queries, while a virtual multi-agent system analyzes complex production data in real-time to identify quality deviations.

Additionally, the site is being transformed into a center of excellence for manufacturing high-tech electric motors, with production of cutting-edge axial-flux motors beginning next year. This innovation has resulted in more than 30 patent filings for new production techniques.