Spinning Away Carbon: New Tech Tackles Cement Emissions

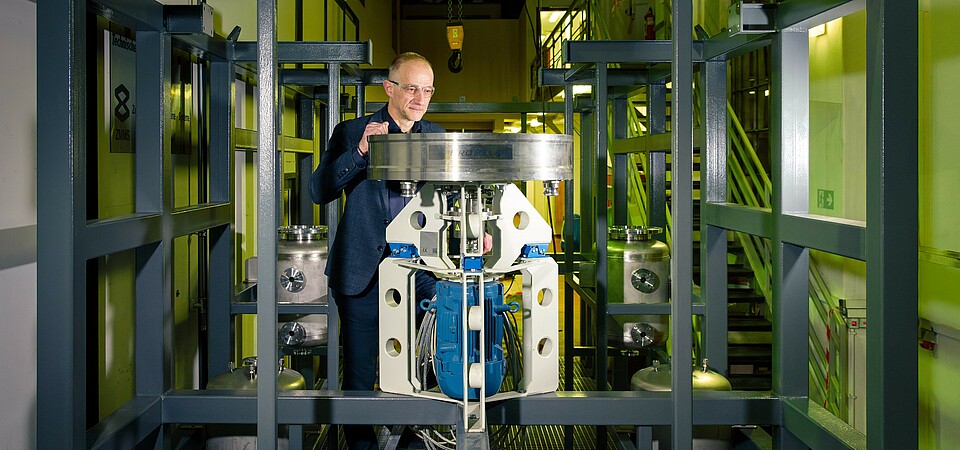

Lower emissions in the cement industry: Prof Dr Jens-Uwe Repke next to part of the pilot plant for CO2 reduction at TU Berlin - © Kevin Fuchs

A washing machine for greenhouse gases? That's essentially the principle behind an innovative CO2 capture technology being developed through a collaboration between TU Berlin, thyssenkrupp Uhde GmbH, and building materials company Holcim. According to information from TU Berlin's press release, this promising approach could significantly reduce the carbon footprint of the cement industry, which currently accounts for eight percent of global industrial emissions.

The technology utilizes a chemical absorption process called amine washing, performed in a rotating apparatus. "You can think of it like a washing machine," explains Jens-Uwe Repke, who leads the Department of Process Dynamics and Operations at TU Berlin. "The exhaust gas is directed into a rotating drum called a packing. There it comes into contact with a special washing liquid, the amine solution, which binds the CO2."

What makes this technology special are rotating packing elements made of metal foam that offer a large surface area in a small space. "The rotating components use centrifugal forces, similar to a carousel," says Olaf von Morstein, project coordinator at thyssenkrupp Uhde. "They ensure that the liquid is guided through the metal foam, achieving intensive mixing of gas and washing agent. This allows us to filter out more CO2 in less time in the smallest possible space – and with less energy input."

The system is currently being tested with real exhaust gas streams at a pilot plant in Holcim's cement factory in Beckum, North Rhine-Westphalia. Initial results are encouraging, with the plant able to remove more than 90 percent of carbon dioxide from exhaust gases.

"We're connecting basic research with practical application," says Repke. "Our models work in the laboratory – but what's crucial is that the technology also proves itself in industry." The TU Berlin team is developing mathematical models to scale the technology to industrial proportions.